Shop

Cat® 316 GC

Original price was: $400,000.00.$350,000.00Current price is: $350,000.00.

- Description

-

- The 316 GC offers best in class performance and Productivity with Low operating costs.

Description

Cat® 316 GC

- Operating Weight

- 14400 kg

- Engine Power

- 68.2 kW / 91 hp

- Bucket Capacity

- 076 HD / 0.8 GD

- Description

-

- The 316 GC offers best in class performance and Productivity with Low operating costs.

INCREASED

PERFORMANCE

- Up to 5% lower fuel consumption*

- Up to 10% more swing torque*

- Improved stability and more drawbar pull*

UP TO

25% LOWER MAINTENANCE COST

- New extended life fuel, hydraulic oil and air filters

- Pilot and case drain filter no longer needed

- Daily ground-level maintenance access

DESIGNED

FOR DAILY WORK

- Easy to operate

- Easy to maintain and repair

- Uncompromised reliability and durability

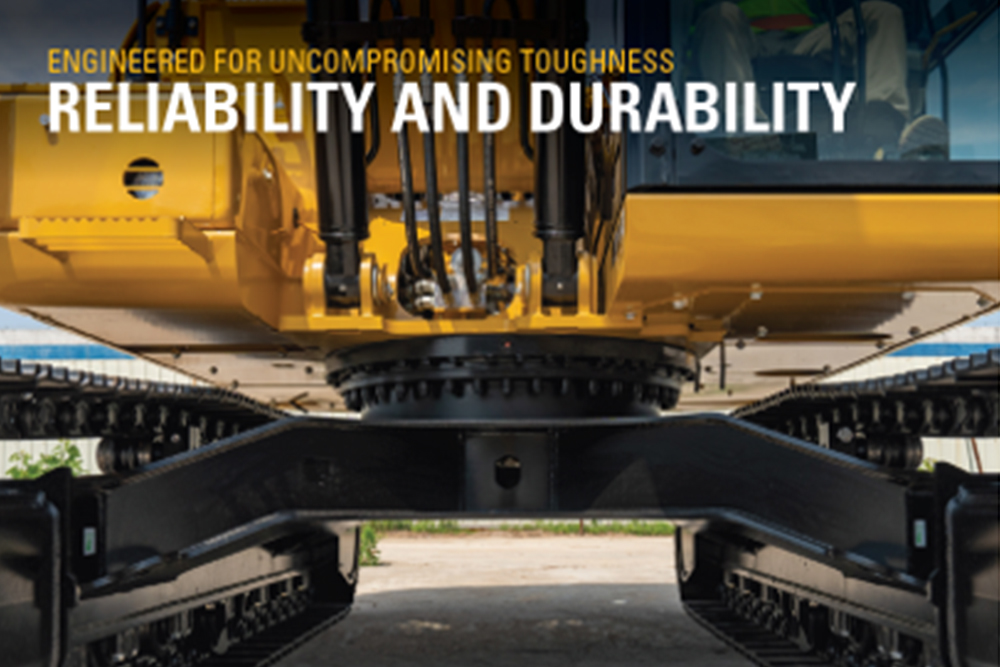

TOUGHNESS RELIABILITY AND DURABILITY

Undercarriage rollers are rebuildable and saaled to prevent dit and debris fram couning internal wear. Gruase lubricanud Inko minimize internal bushing weet, reducing noise and increasing life up to 25. Two robust undercarriage options providing optimized statybosed on bucket selection.

We designed the heavy-duty stick and boom structures using high sta fabricated into a large box section using internal baffles to absorb torsional stress for longer life in quarry applications.

The X-shaped, bos-section carbody provides sscallart resistance to torsional bunding, dissipating struns throughout the base of the machine.

Hydraulic System

INCREASE EFFICIENCY WITH AN

- Entire Pilot system replaced by Electro Hydraulic technology.

- Entire Pilot system replaced by Electro Hydraulic technology.

- Significant reductions in hydraulic hose length and number of connections reduces potential for leaks

- Lower fuel consumption while maintaining controllability

- Customization to operator preference / style

- Lower maintenance cost

- Completely redesigned cab with multiple adjustment seat.

- New touch screen monitor

- Key-less Push to start

- New consoles & Radio with Bluetooth

- Optional rear view camera on monitor

- Optional ROPS & FOG

The 316 GC’s hydraulic filtars have increased service life. The hydraulic pilot filter has been oliminated, and the case drain filter has been replaced by a magnet and mash.

The swing drive is now integrated with the hydraulic system, sliminating the need to check or refill a separate oil system.

The refill capacities for most fluids have been reduced with no change in performance or service life.

Almost all daily maintanance can be performed from ground level. Plus, nearly all major mechanical components are accessed from the ground or the service platform, and an automatic tensioner ensures you will never need to make belt adjustments.

Remotely monitor maintenance alerts, hours, and machine location, viewing the data anytime, anywhere with the online VisionLink” system. Use Cat technology to make informed decisions that will simplify maintenance, boost productivity, lower costs, and improve safaty and secunty on your jobsite.

- Front cabin grill for Operator safety

- Standard LED lights for better night visibility

- Standard engine emergency stop switch from ground level

- Anti skid plates on the service platform and steps

INCREASE YOUR PRODUCTIVITY AND PROFIT

You can easily expand the performance of your 316 GC by utilizing a variety of Cat attachments. Each Cat attachment is designed to fit the weight and horsepower of the Cat excavator for improved performance, safety, and stability.

WEAR AND TEAR

Protect your hammer from overworking. Auto hammer stop warns you after 15 seconds of C continuous firing and then automatically shuts it off after 30 seconds – all to prevent wear and tear on the attachment and excavator.